Resource management and planning of industrial projects

Resource optimisation in industry with PlanningPME

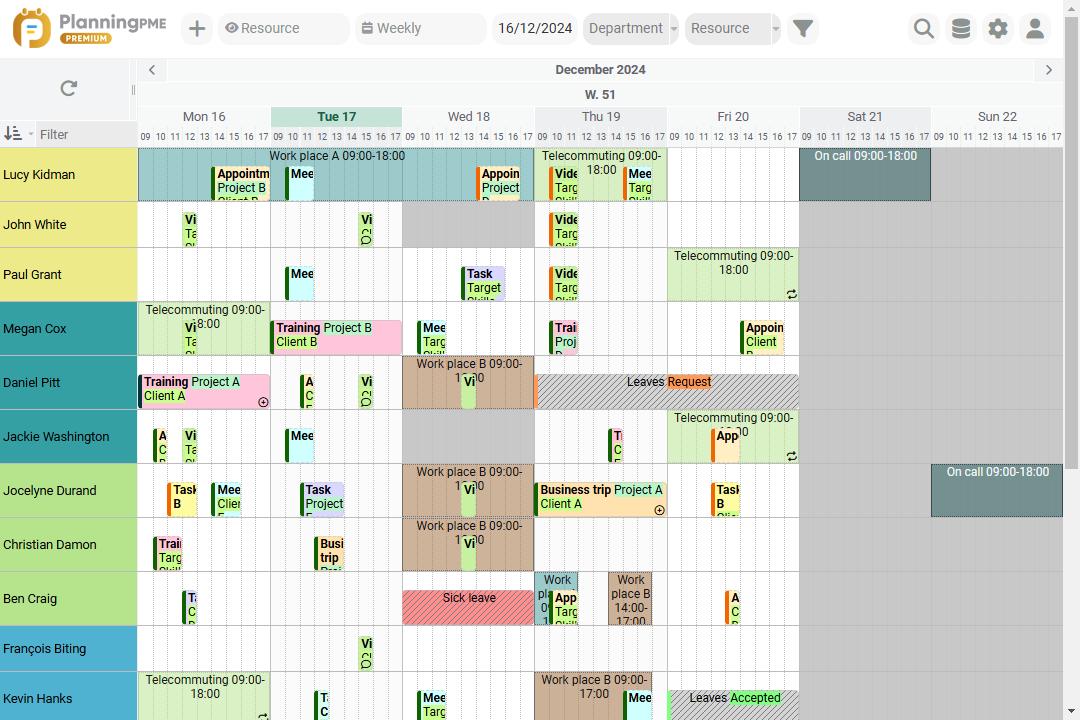

In an industrial sector where organisational rigor is essential to ensure project success, international companies specialising in technical services have chosen PlanningPME to optimise the management of their human and material resources. This strategic collaboration has helped overcome several operational challenges while improving the overall performance of teams and projects.

A demanding sector, complex needs

Companies operate in a highly specialised technical environment, where projects flow seamlessly and overlap. Whether it's construction, maintenance, design, or automation, each task requires precise coordination of teams, machines, and equipment. Projects involve dosens of specific trades and skills, including:

- Management and coordination positions : Activity manager, business manager, site manager, site manager and team leader.

- Specialised technical professions : Automation, programming and network systems, methods and execution.

- Operational resources : Mechanics, boilermakers, pipefitters, welders and roboticists.

The diversity of roles, combined with multi-site and multi-domain projects, makes schedule management particularly complex. PlanningPME acts as a real lever for simplification and optimisation.

Rigorous and centralised task planning

With PlanningPME, businesses have implemented a clear and standardised planning process. Each task is precisely tracked according to four progress statuses:

- Not started

- In progress

- Finished

- Blocked

For example: when a construction manager needs to plan an execution phase on a complex construction site, they can track progress step by step in real time, or if a task is flagged as "Blocked," managers can immediately respond by allocating other resources or reorganising priorities. This real-time visibility is essential to avoid delays and ensure deadlines are met.

Use the resource scheduling template

Optimal management of human resources

One of the major challenges in such a demanding sector is time-off management. PlanningPME provides a comprehensive, centralised view of availability and unavailability for each resource. Absences are categorised according to specific reasons:

- Annual leaves

- Sick leaves

- Professional training

- Compensatory rest, adjustments, time off in lieu of hours worked

- Paternity leave, on-call duty, paid holidays

For example, when a project manager or business technician is absent for professional training, the solution makes it possible to anticipate this absence and reassign their tasks to other collaborators to ensure project continuity.

Optimisation of hardware resources: guaranteed availability

In addition to human resources, PlanningPME also enables efficient management of material resources. For a fleet of vehicles and equipment used daily, availability is critical. Here are some concrete examples:

- Renault Master and Peugeot Boxer utility vehicles are assigned to specific construction sites.

- The handling platform is reserved for specific missions.

With PlanningPME, each material resource is allocated according to project needs, avoiding usage conflicts or logistic delays.

A solution adapted to modern working contexts

Companies have been able to take advantage of PlanningPME to adapt to new ways of working, including:

- Office and remote working : Flexible management that promotes productivity.

- On-call and hotline support : Precise scheduling for on-call and technical supervision teams.

- Part-time work (50%) : Better visibility for alternating or adjusted resources.

This flexibility helps improve team satisfaction while meeting operational requirements.

Concrete benefits for the company

Since adopting PlanningPME, companies have seen significant improvements:

- Time optimisation : Reduced hours spent on manual planning.

- Predicting scheduling conflicts : Better management of absences and material resources.

- Accurate project monitoring : A real-time view of tasks, their progress and blockages.

- Increased flexibility : Ability to adapt to new ways of working and unforeseen events.

- Improved communication : A shared and centralised vision for all teams.

PlanningPME: A strategic asset for optimised management of industrial projects

By integrating PlanningPME into their organisation, these companies have successfully met the challenges of a complex industrial sector. Our software has simplified project planning, optimised human and material resources, while ensuring greater productivity. If, as a company, you want to optimise the management of your teams and projects, PlanningPME is the tool you need to take things to the next level.

They trust us

I really like the quarterly view, which lets me look at 13 weeks of planning. I also like that we can scroll forward in time very easily. This is particularly helpful as a lot of our projects are planned well in advance. I also like that we can have colour codes for different resource groups and different tasks.

Unista

FAQ

Industrial companies must manage complex projects involving numerous technical skills, varied tasks, and often limited human and material resources. PlanningPME enables precise and centralised planning of teams and equipment, better absence management to anticipate unavailability, real-time monitoring of task progress, and rapid detection of blockages. This allows companies to optimise their organisation and meet deadlines.

With a centralised, global view, PlanningPME categorises absences (annual leaves, sick leaves, training, etc.). When an employee is unavailable (for example, due to annual leaves or professional training), the tool allows for quick identification of affected tasks and reassignment to other available resources. This ensures project continuity without major disruption.

PlanningPME integrates efficient material resource management by scheduling their use according to project needs. For example, if vehicles like the Renault Master or the Peugeot Boxer need to be mobilised for specific assignments, the tool avoids usage conflicts by optimally scheduling each resource. This reduces downtime and improves productivity in the field.

The tool offers great flexibility by adapting to different modern work contexts, including: office and remote working for administrative or research teams, on-call for urgent interventions and hotline support, and part-time (50%) and alternating work for a hybrid and agile organisation. This adaptability allows industrial companies to take advantage of new ways of working without losing efficiency or visibility.